Piloting a water treatment process can demonstrate the feasibility of a proposed plan. Investing in a pilot project before a full-scale installation can save money, avoid headaches later, and set your project up for success. For Green River, Utah, testing and then tweaking their treatment process was a strategy that proved successful.

Providing Consistent Water Quality for the Community

For the small city in eastern Utah, piloting the water treatment system at the Green River Water Treatment Plant (GRWTP) helped determine how to handle spring and fall surges in disinfection byproduct (DBP) levels within the distribution system due to higher total organic carbon (TOC) concentrations in the Green River. Increased TOC during those peak times was causing a DBP issue that couldn’t be resolved with the current treatment system.

Green River conducted a pilot project where operators could dive into the treatment options for polishing granular activated carbon (GAC) filters. Figuring out those critical operating parameters showed where to tweak things to optimize a full-scale process design – like fine-tuning a recipe until it is just right.

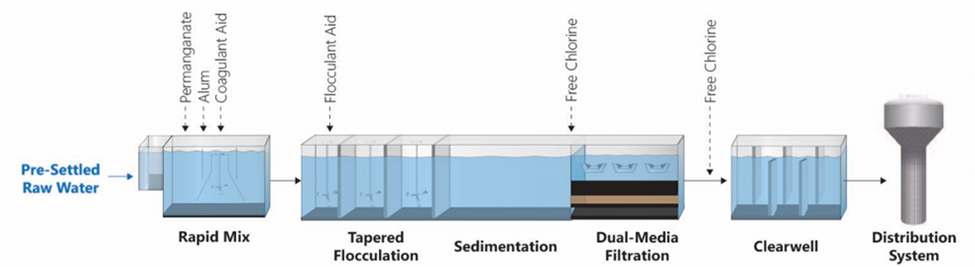

The GRWTP needed the right recipe to provide consistent water quality for its 900 customers and treat nearly 500,000 gallons of water per day from the Green River. Given the fluctuating water quality due to natural hydrologic cycles, the GRWTP needed to develop an operations strategy to optimize its conventional treatment process that includes coagulation, flocculation, sedimentation, dual media filtration, and chlorine disinfection.

Balancing TOC Removal with DBP Formation

The GRWTP operates two identical treatment trains, each with a capacity of 500 gallons per minute (gpm). Potassium permanganate is added early to address taste and odor, while alum is used as the primary coagulant. The flow is split into two trains featuring three-stage tapered flocculation and tube settlers. Each train includes filters with sand and anthracite layers, which have proven effective in reducing turbidity when chlorine is fed at the filter influent. Chlorine is generated by an onsite sodium hypochlorite system. The GRWTP has faced recurring issues with DPBs, specifically trihalomethanes (THMs) and haloacetic acids (HAAs), which occasionally exceed regulatory limits. The GRWTP’s existing filters typically reduce TOC to less than 3 mg/L and remove turbidity to approximately 0.1 NTU. The primary goal of the project was to determine the best way to remove TOC and reduce DBP formations in the distribution system during peak times when DPB formulation potential is greatest. The State of Utah requires that significant water treatment changes are first tested through a pilot project, so AE2S was selected to do the process design at the GRWTP and was also able to provide the filter pilot skid and set up the pilot study. Utah State Revolving Funds were secured on behalf of Green River to finance the pilot study.

Solving the DPB issue could have required any of these traditional approaches:

- Optimize the amount of disinfectant used or reduce the contact time to minimize DBP formation while still meeting regulatory disinfection requirements.

- Switch to a different type of disinfectant to alter the disinfectant residual profile.

- Implement treatment like enhanced coagulation and biofiltration to eliminate precursors and prevent DBPs from forming in the first place.

The Green River pilot testing protocol was developed around the third option: implementing a treatment to eliminate precursors. The pilot was installed in the GRWTP for three months to test the optimization of TOC removal using various granular activated carbon (GAC) filtration media, bed depths, contact times, and loading rates.

Navigating Hurdles

Piloting this treatment approach posed challenges because no two systems are the same. Every pilot study must address the hurdle of providing water to the skid at an appropriate flow and pressure. In the case of Green River, that was diverting enough water from the full-scale filter effluent to run the pilot skid throughout the night, even when the plant was shut down.

The next hurdles were electricity, shelter for the skid, and disposal of the pilot effluent water. Thought needs to be given to sequencing of the scenarios being tested and the monitoring and sampling frequency to ensure reliable data is produced. An interesting finding allowed the design team to select the best media to meet the objectives of the study while dramatically reducing the regeneration frequency, thus saving money and minimizing the operational requirements of changing the media. AE2S was able to define exhaustion criteria that met the desired treatment goals and allowed an objective comparison of the tested media filter.

“We achieved successful outcomes thanks to a knowledgeable, responsive team and engaged operators,” said Marie Owens, PE, AE2S Project Manager. “Spending a few weeks conducting a pilot study will provide extensive cost and operational enhancements to any treatment project and can promote understanding and build confidence in the best path forward.”

Confidence in a Full-Scale Treatment

The GRWTP’s pilot study is a critical step toward enhancing water quality and regulatory compliance for Green River. By optimizing TOC removal strategies, the City aims to reduce problematic DBP formation potential and provide safer, cleaner water to its community while maintaining regulatory compliance. The pilot allowed the project team to tweak the final treatment process design to maximize the media lifespan and constituent removal, adjusting for circumstances that they couldn’t foresee ahead of time. And with confidence, the project has moved forward into the full design phase. This project benefits the residents of Green River and showcases AE2S’ expertise in creating pilot environments to test and determine optimal water treatment solutions for unique situations.